Mechanical Properties

ETFE foils have a very high durability compared to other transparent plastic materials. High tensile strenght, extraordinary tear and impact strength of ETFE foil are the basic properties of an ideal membrane material. ETFE is a very ductile material and demonstrates good failure behaviour thanks to its large deformations before breaking point. ETFE foils are also alkali and solvent resistant to a great extent.

Why ETFE instead of Glass?

Compared to glass, ETFE film is lighter, transmits more light and is also resilient. Its properties like self-cleaning due to its nonstick surface and recyclability at lower cost are superior. When using pressurised pillows, its possible to achieve control of both sunlight transmission and effective insulation. ETFE coverings offer also excellent acoustic properties, as the material does not cause annoying echoes indoor. Unlike glass ETFE film is shatterproof.

Light Transmission

The optical characteristics of the transparent ETFE foil are very advantageous. Alongside its low weight, the major benefit of ETFE is its high translucency by transmitting up to 94-97% of visible light (380-780nm) and 83-88% of ultraviolet range (300-380nm). This is a vital property for well being of humans and plants. The nearly natural daylight makes the indoor environment more enjoyable in projects like shopping malls, indoor swimming pools, atrium roofs, market places, football stadiums and tennis courts. ETFE cushions can be lit internally with LED lighting to make them glow or projected onto externally like a giant cinema screen, creating dramatic results.

Thermal and Chemical Characteristic

A standard three-layer cushion has a U-value of around 1.95 W/m2K. This is considerably better than triple glazing when used horizontally. The cushion's insulative characteristic can be further enhanced by addition of further layer which can also be treated with Low E coating. This approach could reduce the U-value to below 0.6 W/m2K.ETFE foil also absorbs a large proportion of infrared light transmitted, a quality which can be used to improve energy consumption of buildings.

Design

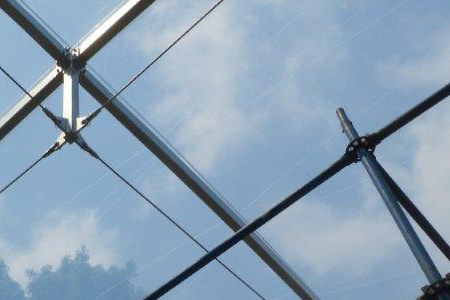

ETFE foil roofs can be supplied as a single layer membrane supported by a cable net system or commonly as a series of pneumatic cushions made up of two to five layers of ETFE. Whether it is a single layer or in cushion forms, ETFE foil systems are supported in an aluminium extrusion at he perimeterwhich in turn, is supported by the main building frame. In the case of ETFE cushions, they are kept continually pressurised by a small inflation unit which maintains the pressure at 200-600 Pa and gives the foil a structural stability and the roof some insulation properties.

Twitter

Facebook

Google

Instagram

Linkedin